About Us

Strategic Outlook

Tampa Bay Machining is an industry leading manufacturer of precision machined components supporting Aerospace, Defense, Space, Commercial, and Industrial applications. Our team located in Tampa, FL aims to provide an extraordinary experience for our customers by delivering quality products on time and with great value.

At Tampa Bay Machining, we have adopted our parent company Princeton Precision Group motto, “Always Advancing”. TBM is always searching for new ways to improve our ability to meet the ever evolving needs of our customers. We tirelessly invest in our people and facilities with the objective to add value to our customers. These values include but are not limited to product quality, program delivery, new capabilities, and expansion. We strive to offer a simplified supply chain solution to all of our customers.

Over the past few years Tampa Bay Machining has invested millions into new resources, technologies, and property to support our customer needs. With the promising outlook from the growth of our customers this trend will continue.

Our pledge remains, Always Advancing!

Our History

Since our inception in 1981 Tampa Bay Machining has provided parts and services to some of the largest corporations in the world while still working side by side with startup local businesses. After years of supporting local businesses in the Tampa Bay area with their various needs TBM began focusing more on support of the Defense and Aerospace sectors.

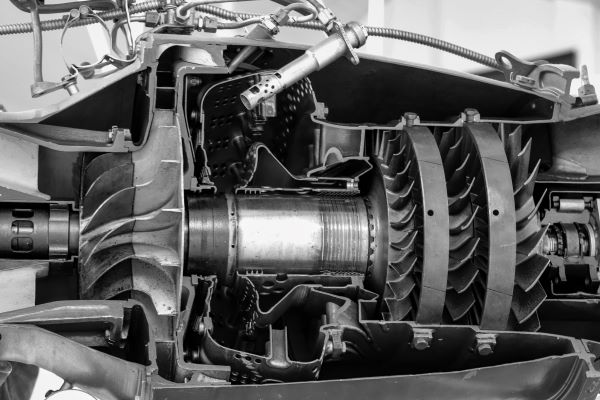

Over the years TBM has manufactured components for spectrometers, commercial gun accessories, defense missiles, to space application parts. For many years TBM has been called on by industry leading companies to produce high-rate production needs. Due to TBM’s stellar track record Princeton Precision Group acquired them in October 2021. With the increased backing of Princeton Precision Group Tampa Bay Machining commitment to quality and on time delivery continues.

Capabilities

Tampa Bay Machining provides precision CNC milling, CNC turning, lapping, and CMM inspection services per your design and specification. TBM also partner with a number of companies to provide a single source solution to include but not limited to anodize, chemical conversion coating, electroless nickel plating, painting, welding, and EDM. TBM is AS9100 rev D certified, and ITAR registered.

TBM manufactures precision machined components from Aluminum, Stainless Steel, Titanium, Copper Alloys, Plastics, and many other materials. Manufactured components range from chassis, brackets, housings, cans, and various components. Tampa Bay Machining is always advancing by continuously improving the manufacturing processes to provide on-time, on-cost, and on-quality products to our customers and partners.

CNC Milling

Our 15 CNC milling machines give us the capacity to meet your small- or large-run production requirements. Six are twin-spindle, allowing us to easily transition between small runs and larger production runs while remaining price-competitive and maintaining extremely tight tolerances. Our practice of employing highly expert operators and using only state-of-the-art milling machines gives you the advantages of exceptional quality product and on-time delivery.

CNC Turning & Lapping

Our 7 CNC lathes are truly state of the art – with features that range from opposing spindles with bar feeding, the ability to turn with “live” milling and “Y”-axis milling capability, to simple chucker-type turning.

Our three-headed lapping machine with a 24-inch-diameter table enables us to lap parts up to approximately eight inches long. This machine allows us to hold flatness callouts as tight as .0001 on many parts

Assembly

Our assembly team installs over a million helicoils every year. But we don’t stop there. We also rivet, install keenserts, all types of swage-lock hardware, and pem studs – in addition to handling numerous other assembly requirements. Your manufactured parts are carefully and precisely assembled using calibrated torque wrenches and/or adhesives that allow us to meet your strictest requirements.